How much do you really know about heavy-duty mechanical anchors?

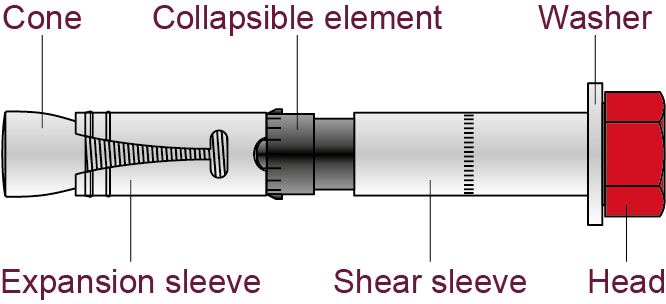

Let’s continue focusing upon anchor plate anchor solutions. After our deep-dive into stud anchor technology, it’s time to check out the features and benefits of heavy-duty sleeve anchors, starting with a better understanding of their components. We will mainly talk about HSL-3 design. As you might expect, some features may change depending on the product.

The cone and expansion sleeve

Similarly to stud anchors, the cone and expansion sleeve are the key elements for the pull-out holding capacity: After the anchor is introduced into the pre-drilled holes (that have been cleaned of dust and fragments), the torque is applied to the head. This, in turn, causes the wedge to be drawn into the expansion element, which expands against the wall of the bore hole securing the anchor and guarantee its capability against the pull-out.

The collapsible element

A relevant piece to ensure the right installation safety, the collapsible element mainly has two functions. Firstly, to prevent rotation of the sleeve during the application of the torque. Secondly, to guarantee, thanks to its telescopic deformation, that the expansion sleeve is not compressed in any way if the shear sleeve comes into contact with the washer.

Shear sleeve

The cylindric steel element, called the shear sleeve, guarantees extra shear load capacity on steel in some conditions. It can be very helpful in shear-relevant applications.

Head configuration: Have you ever heard about torque limitation nuts?

This technology usually comes with a different head finishing. The hexagonal bolt and the nut version (first and second image in the next picture) don’t need further explanation, and we already explained the benefits of the countersunk version (third image) when talking about screw anchor technology.

Let’s focus on a one-of-a-kind head finishing: the torque limitation nut version (last image). The anchor comes with the addition of a cap on top of the nut (with red color for HSL-3), which permits the proper setting without a torque-indicator wrench: When the anchor is tightened, the torque is transmitted through the cap itself, which will break free when the right installation torque is attained.

This system prevents over-torqueing (the cup breaks) and under-torqueing (when the cup remains in place, this indicates that the head has not been tightened enough), thus increasing the safety of the installation and enabling easier inspections.

Different head finishing: Hexagon bolt (a), stud (b), countersunk (c) for flush fixing, with torque limitation nut (d)

When should you use a sleeve anchor for anchor plate fixing?

Firstly, the right anchor selection depends on loads and condition requirements. Any anchor solution that is qualified for the application conditions (i.e. static, seismic, fire) and complies with design requirements is technically suitable. However, there are some aspects you might consider when selecting a sleeve anchor instead of other technologies:

· Compared to other torque-controlled expansion anchors, it is easier to introduce into the bore hole, making this part of the installation (hammering) more comfortable for the installer, especially in an overhead setting and for large anchor sizes. On the other hand, the bore hole size is bigger, requiring more drilling effort, and the installation torque might be higher than for a stud anchor, for example;

· It is partially or completely removable. In the case of temporary applications, it is an asset;

· In safety-relevant applications, the torque limitation nut makes the installation more reliable;

· For aesthetic reasons (i.e. architecture), hexagonal head and countersunk are preferred.

Are you ready for your next anchor design with HSL-3? It's time to experience our software PROFIS Engineering. If you need further information, we can help you. Simply leave a comment on this article or post your question on our discussion board.